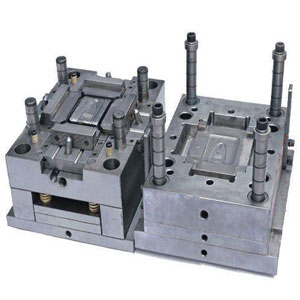

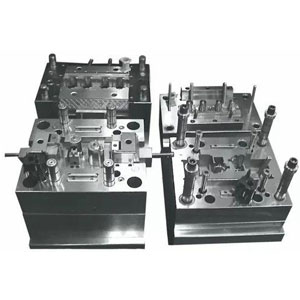

An Injection Moulding Die is a crucial tool used in the injection moulding process, where it shapes molten plastic into a desired form. It consists of two primary parts: the core and the cavity. The cavity side holds the negative shape of the part, while the core side forms the internal features. When these two parts come together, they create a mold cavity where the plastic is injected, cooled, and solidified, producing a finished component.

Injection moulding dies are made from durable materials like steel or aluminum to withstand high pressure and repeated use. The design and precision of the die are vital for achieving consistent product quality and efficiency. Proper maintenance and care are essential to extend the life of the die and ensure the production of defect-free parts. Dies are used across a wide range of industries, including automotive, electronics, medical devices, and consumer goods, making them an integral part of modern manufacturing.